02 Ara

Madeni yağ, genel olarak farklı viskoziteye sahip baz yağlar ile çeşitli birçok katkı maddesinin birleştirilmesi sonucu elde edilir. Yağlardan beklenen özelliklere göre söz konusu katkı maddeleri değişiklik gösterebilir.

Tam da bu nedenle, üretim sırasında kullanılacak olan katkı maddelerinin yapısal olarak hangi özelliklerine göre seçileceğini belirlemek oldukça önemlidir. Baz yağ ise yağın topraktan çıkarıldığı haliyle yani ham olarak rafine edilerek bileşimin bir parçası haline gelir.

Madeni Yağ Kullanım Amacı

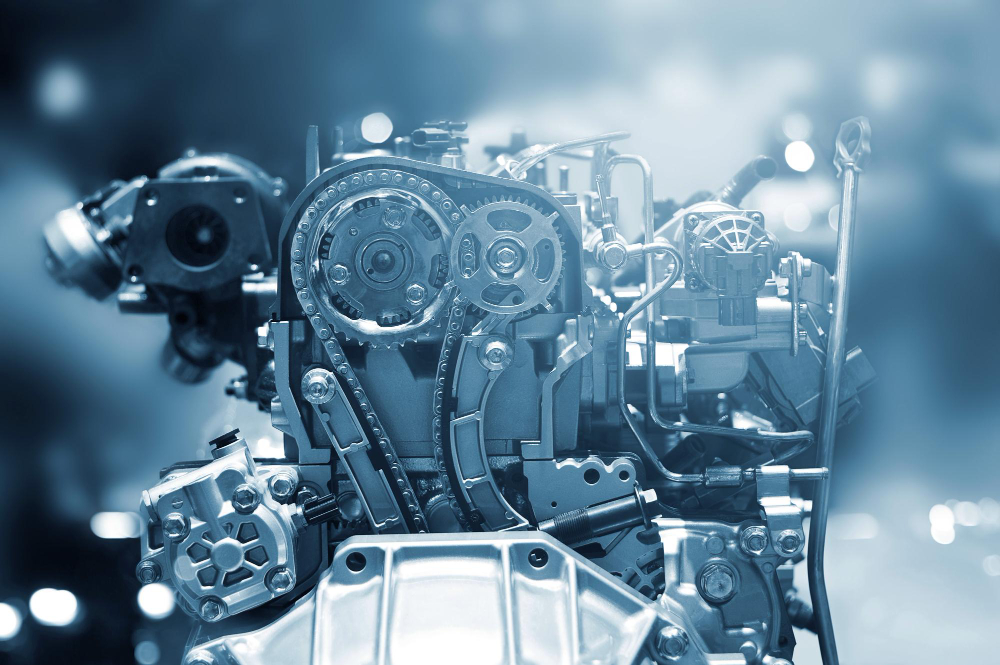

Makinelerin parçaları ne kadar kusursuz üretilirse üretilsin, parçaların yüzeylerinde kusursuz bir parlaklık ve düzgünlük sağlanması oldukça zordur. Bu parçaların yüzeylerinde asperit adı verilen ve görülmesi ancak mikroskopla mümkün olan girinti ve çıkıntılar mutlaka oluşacaktır.

Bu girintiler iki yüzeyin uzun süre boyunca devamlı olarak birbirine temas etmeleri sonucu oluşurlar. Aynı zamanda madeni yağ kullanılmayan parçalarda yüzey hareketlerinin direnç göstermesine ve sürtünmenin artmasına da neden olurlar.

Madeni yağ kullanımının asıl amacı da bu sürtünmeyi olabilecek en iyi şekilde azaltmaktır. Madeni yağ durmaksızın birbiri ile temas eden yüzeylerin üzerinde bir film tabakası oluştur ve iki katı cismi bu şekilde birbirinden uzaklaştırarak parçaların çok daha rahat hareket etmesine yardımcı olur.

Madeni Yağ Üretimi Nasıl Yapılır?

Ham petrolün rafine edilmesi işlemi ile üretilen ürünlerden biri de madeni yağ olarak adlandırılan bir yağlayıcıdır. Üretimi sırasında petrol rafine işleminin ardından tekrar özel işlemlerden geçirilerek, hammaddesi olana bazı baz yağlar elde edilir.

Madeni yağ, farklı viskozitelere sahip baz yağlara, beklentileri karşılamak üzere seçilen çeşitli katkı maddelerinin karıştırılması sonucu elde edilir. Yağ seçiminde kullanım amacına uygun seçim yapmak kritik öneme sahiptir.

Madeni Yağlar Arasındaki Farklar Nelerdir?

Sektörde birçok cins madeni yağ bulmak mümkündür ve bu yağların tamamında kullanılan hammadde aynıdır. Ancak yine de yağların üretimlerinde kullanılan malzemelerin farklı seçilmesi ile baz yağları farklılık gösterebilir.

Bu farklılıkları ortaya çıkarak iki sebepten söz edilir. Madeni yağ üretiminde kullanılan baz yağlarının kimyasal özelliklerinin farklılıkları, kullanılan katıların miktarı ve cinslerinin farklı olması ayırımı ortaya çıkaran faktörlerdir.

Madeni Yağların Sınıflandırılması

Madeni yağ içerdiği kimyasallar ve katkı maddelerine göre, “Mineral Bazlı Yağlar” ve “Sentetik Bazlı Yağlar” olarak iki farklı grupta sınıflandırılır.

Mineral Baz Yağlar

Kimyasal yapıları ve yağlara kattıkları özellikleri bakımından 3 grupta incelemek mümkündür.

1. Alifatikler :

Molekül yapılarında, çeşitli atomların birbirlerine kovalent olarak bağlanması sonucu oluşmuş, düz veya zincirli bir şeklinde iskelet içeren organik bileşik ve türevleridir.

– Parafinik :

Parafinik yağlar, hydrocracking süreç veya ekstraksiyon yöntemi yoluyla rafine edilir. Yüksek parlama noktaları, düşük volatilite, iyi renk kararlılığı gösterirler. Bu yağlar özellikleri bakımından istikrar gerektiren yüksek ısı ortamlarında ve düşük renk gerektiren uygulamalar için oldukça iyi bir seçenektir.

– Naftanik :

Naftanik yağların madeni yağ seçenekleri arasında yaygın olarak kullanılan uygulama seçenekleri vardır. Geniş bir viskozite aralığına sahip olan bu yağın aynı zamanda flaş, geri ödeme gücü ve renk rafine özelliğini barındırır.

2. Aromatikler :

Parafinik yağ üretiminde, aromatik çıkarılması sonucu aromatik yağlar elde edilir. Koyu renge, düşük anilin noktalarına, nispeten yüksek parlama noktalarına ve yüksek aromatik içeriğe sahiptir. Aromatik yağlar, madeni yağ endüstrisinde geri ödeme gücü bir ölçüde yüksek yumuşama için istenen veya akışkanlaştırıcı etkisinin olduğu normal uygulamalarda kullanılır.

3. Alifatik ve Aromatik :

Kusursuz bir şekilde üretilen parçaların yüzeylerinde dahi tam bir parlaklık ve pürüzsüzlük sağlamak mümkün değildir. Bu nedenle parçaların parlak ve düzgün olması için mutlaka madeni yağ kullanılmalıdır.

| MADENİ YAĞ TEKNİK TABLO | MİNERAL YAĞLAR | SHC (PAO) | POLİGLİKOLLER |

| Yoğunluk (g/ml) 20°C’de | 0,9 | 0,8…0,9 | 0,9…1,1 |

| Viskozite Index (VI) | 80…100 | 100…130 | 150…270 |

| Donma Noktası (°C) | -40…-10 | -40…-25 | -56…-23 |

| Alevlenme Noktası (°C) | < 250 | < 250 | 150…300 |

| Oksidasyon Dayanımı | Orta | İyi | İyi |

| Isıl Dayanım | Orta | İyi | İyi |

| Yağlama Kabiliyeti | İyi | İyi | Çok İyi |

| Sızdırmazlık Elemanları Uyumu | İyi | Orta | İyi |

Alifatik bileşikler alkan, alken, alkin veya bunların türevleri gibi reaksiyon gösteren araçlara verilen isimdir. Aromatik bileşikler ise benzen türevleri veya benzen heterosiklik gibi bileşenlerdir.

Not: Oksidasyon yağın çamurlaşmaya başlaması anlamına gelir. Madeni yağ oksidasyon göstermeye başlamışsa mutlaka değiştirilmelidir.

Sentetik Baz Yağlar

Mineral esaslı baz yağlarının özellikleri, ham petrolün gösterdiği yapısal özellikleri ile sınırlandırılır. Aynı zamanda son yıllarda dünyada çapında petrol üretiminin azalmasına bağlı olarak petrol fiyatlarındaki hızlı artış görülür.

Günümüzde hızla gelişen teknolojiye bağlı olarak çok daha zor şartlarda çalışabilecek yağlara gereksinim duyulur. Bu nedenle de sentetik madeni yağ kullanılması ile ilgili çalışmalar her geçen gün hızla artmaktadır.

Sentetik Yağlar Nasıl Elde Edilir?

Petrol esaslı olmayan kimyasal sentez yöntemleri sonucu sentetik yağlar elde edilir. Bu aşamada kimyasal proses kullanılarak sentetik bir yapı meydana gelecek şekilde hidrokarbon moleküller şekil ve boyut açısından birbirlerinin benzerleri olacak biçimde tasarlanırlar.

Sentetik yağların yapısı özenle düzenlenmektedir. Bu sayede sürtünme seviyesi minimuma indirilir, sıcaklı düşürülür, aşınma azaltılır ve enerji tasarrufu maksimum seviyeye çıkartılır. Tüm bu özellikleri sayesinde madeni yağ içerisinde yer alan sentetik yağlar üstün özellikleri ile tercih edilir.

Düşük sıcaklıklarda kolay akarlar ve yüksek sıcaklıklarda da incelmezler. Oksidasyon özelliklerinin yüksek olması ve ısıl mukavemetleri sayesinde makinelerin kullanım ömrünü önemli ölçüde uzatırlar.

Sentetik yağlar laboratuvar ortamında özel bir teknoloji kullanılarak üretilirler. Madeni yağ türevlerinden biri olan mineral yağlara oranla çok daha yüksek ve düşük sıcaklıklara karşı dayanıklıdırlar. Aynı zamanda yüksek basınç ortamlarında da kusursuz çalışırlar.

Başlıca Sentetik Baz Yağları

- (PAO)

- Alkali Aromatik

- Alifatik Diester

- Polyolester

- Polybutenes

- Phosphate Ester

- Polyalkenglycol

Madeni yağ bünyesinde yer alan sentetik yağlar, hammaddeleri bakımından ve üretimlerinde yüksek teknoloji kullanılması nedeniyle maliyeti oldukça yüksek olan ürünlerdir. Bu nedenle de sentetik yağlar madeni yağlar ile kıyaslandığında biraz daha pahalıdır. Böylece madeni yağ fiyatları üretimlerinde kullanılan malzemeler bakımından değişiklik gösterir.